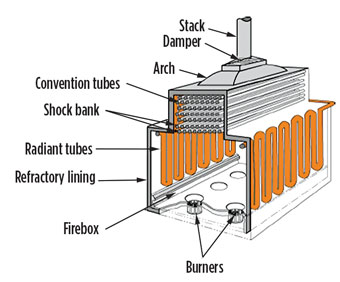

6 Heater type v v v v v v Vertical Cylindrical Low plot space Lower number of burners Compact Convection Design Lower cost Large burners-low burner to tube clearance v Horizontal Box v More plot space (including tube pulling) v Higher number of burners v Long convection section v Higher cost 7 Heater Types VC Heater Horizontal Box Heater 8 VC vs.

v Lowest cost heater may have high H/D or H/W ratio (tall and lean firebox causing flux imbalance) v Heater design is complicated and needs to be paid attention. v Lowest cost heater may have smallest radiant section resulting in higher heat flux or short run length. v How can you compare the heater designs if they are designed differently? v Most engineering companies lean on heater vendors and choose the most economical design (lowest cost) 5 Process Design Parameters v Lowest cost heater may have higher flue gas temperature or lower thermal efficiency. v Major reasons for limited run lengths appear to be coking and high tube metal temperatures 3 Heater Specifying Process v Process Licensor/Client provides the process heat duty and terminal conditions (in/out) v It is provided to Engineering Companies for developing FEL-2/3 estimates v Engineering Companies add missing details and floats inquiries to heater vendors to get their budgetary proposals v Engineering Companies firm up heater specifications and issue firm inquiries for supply 4 API 560 v It leaves the process design of the heater to vendors. v Any unexpected heater shutdown costs Millions of Dollars production loss. The heater should be able to continuously run for 5 years before it is shut down and cleaned. For most services, it is around 4-6 years. In this paper, I have made an effort to bring up some of the issues that have impact on fired heater performance and reliability significantly.īetter Fired Heaters Specifications Pay Off Ashutosh Garg - Furnace Improvements Sugar Land, TX Fired Heaters Changes v Changes in the last 30 years v No more fuel oil firing v No more sodium and vanadium in the fuel v No more high sulfur content in the fuel oil/gas v No more soot blowers v Lowest NOx emission v Highest efficiency v Carbon tax-GHG emissions v Burners flames are 2-3 times longer are that of standard burners v No more air preheater 2 Heater Run Lengths v Heater run length is very important to owners and operators. There are a number of issues that have not been addressed in API-560. Fired heaters design and requirements have been real complex. They analyzed the changes that were made in the specifications. Furnace Improvements recently compared all the five editions of API. API recently published 5th edition of API 560. API 560 was first published in 1986 and in the last 30 years, they have come out with many improvements in the design and specifications API 560 is a very good starting point for specifications.

API took over this job in 1980's and produced a standard called API560. Major developments in fired heater designs and specifications were mostly taken care by Oil Companies for a very long time. It is very important to specify the fired heaters correctly. Today's fired heaters must meet demands for process performance, efficiency, operability, and safety, which have become very important issues. Most of the fired heaters last 40-50 years so it is not easy to change them once they are built. They are one of the most expensive and long delivery items. Paper from the AFRC 2018 conference titled Better Fired Heaters Specifications Pay Offįired heaters are one of the most important equipment in the refining industry.

Better Fired Heaters Specifications Pay Off

0 kommentar(er)

0 kommentar(er)